WHAT IS DRY ICE?

Dry ice is the solid state of carbon dioxide (CO₂) formed at a temperature of -79 °C.

Carbon dioxide is naturally found as a gas on Earth. It is non-toxic and odourless, and often used to saturate drinks to give them a fresh taste and prolong consumption. Dry ice is also used in the food industry to cool food or applied in health services.

WHAT IS DRY ICE CLEANING?

The cleaning process applies three basic phenomena: kinetic energy, thermal shock, and sublimation. The process only removes residues and no secondary waste is produced. Dry ice blasting is a cleaning method which is effective, gentle on the cleaned materials and environmentally friendly. Dry ice lets you gently and ecologically clean deposits of sediment and residue without needing to dismantle any of your equipment. You therefore save time and considerable monetary costs.

Dry ice is known to inhibit the growth of bacteria. The dry ice cleaning process also stops the growth of fungi and spores and reduces the presence of other biological contaminants. It is also non-toxic, odourless and suitable for any surfaces – metal, wood and concrete, even on fine wood grains, glass or textiles.

KINETIC ENERGY

The impact velocity of dry ice pellets on a contaminated surface can exceed even the speed of sound.

THERMAL SHOCK

Contaminated layers become brittle after rapid cooling and are gradually released from the cleaned surface.

SUBLIMATION

After contact with the contaminated surface, the pellets change their physical state and become a vapour, perfectly removing any contamination

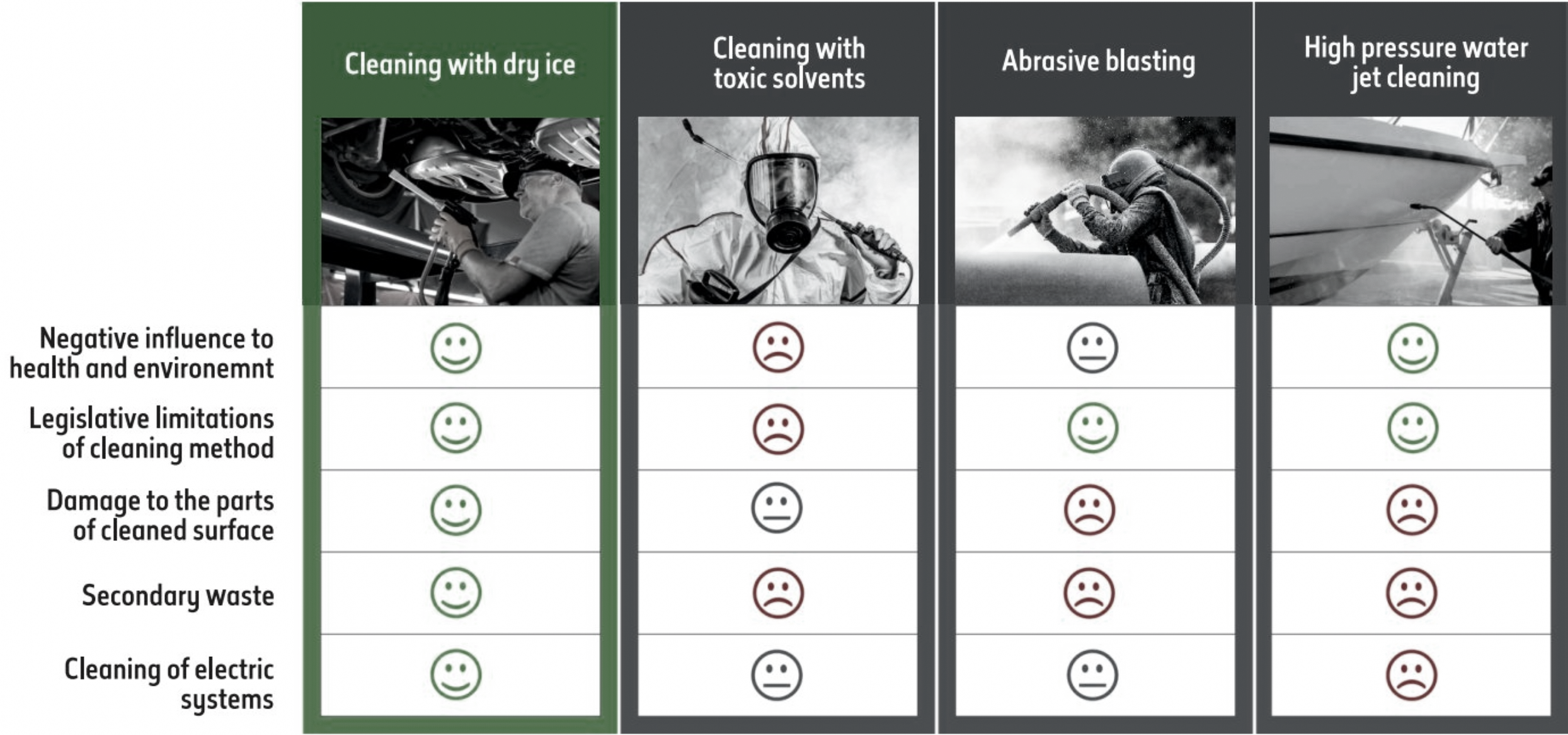

COMPARISON TO OTHER METHODS

Increased productivity and economic efficiency, stricter conditions for environmental protection, and employee safety during when technological equipment is cleaned and maintained requires more modern technologies to be applied.

Dry ice cleaning ideally meets these requirements and becomes an important alternative to conventional cleaning procedures. Blasting machines with dry ice saves a significant amount of time since it is not necessary to disassemble and subsequently reassemble machine parts.

Abrasive Blasting

High-Pressure Water Cleaning

Cleaning using Toxic Solvents

Using abrasive elements (glass or plastic granulate) damages the surfaces of cleaned parts and reduces their service life. Dry ice pellets are non-abrasive and extremely gentle to cleaned surfaces.

Unremoved blasting medium residue can significantly impair production processes. Dry ice pellets evaporate immediately during cleaning, so there is no risk.

Residues after blasting require separate disposal, often post-treatment. Dry ice cleaning generates no secondary waste – dry ice sublimes immediately.

High-pressure water cleaning damages the surfaces of cleaned materials.

Dry ice pellets are non-abrasive and do not damage cleaned surfaces.

High-pressure water cleaning is unsuitable for cleaning electrical systems.

Dry ice is non-conductive and therefore suitable for cleaning electrical systems and equipment.

Water and residues released by cleaning must be disposed of separately. Dry ice cleaning generates no secondary waste.

Conventionally cleaned areas and equipment require a long time to dry thoroughly. Dry ice cleaning is a dry process, which significantly reduces downtime.

Generally after treatment, solvents require separate disposal.

Halogenated hydrocarbons and other cleaning additives have adverse effects on health and the environment.

Dry ice is non-toxic. The use of toxic solvents is often restricted by law!

No legal restrictions are placed on the use of dry ice.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!